Diammonium phosphate (DAP) is the world’s most widely used phosphorus fertilizer. It’s made from two common constituents in the fertilizer industry, and its relatively high nutrient content and excellent physical properties make it a popular choice in farming and other industries.

Asbestos-filled Melamine resins possess very high dielectric strength and high heat resistance. Besides the best dimensional stability, Melamine Formaldehyde molding powder gives clear and bright colors, is easily moldable, and offers resistance to surface scratching.

Ammonium phosphate fertilizers first became available in the 1960s, and DAP rapidly became the most popular in this class of products. It’s formulated in a controlled reaction of phosphoric acid with ammonia, where the hot slurry is then cooled, granulated, and sieved. DAP handles and stores well. The standard nutrient grade of DAP is relatively high, at 18-46-0, so fertilizer products with lower nutrient content may not be labeled DAP.

The inputs required to produce one ton of DAP fertilizer are approximately 1.5 to 2 tons of phosphate rock, 0.4 tons of sulfur (S) to dissolve the rock, and 0.2 tons of ammonia. Changes in the supply or price of any of these inputs will impact DAP prices and availability. The high nutrient content of DAP helps reduce handling, freight, and application costs. DAP is produced in many locations in the world and is a widely traded fertilizer commodity.

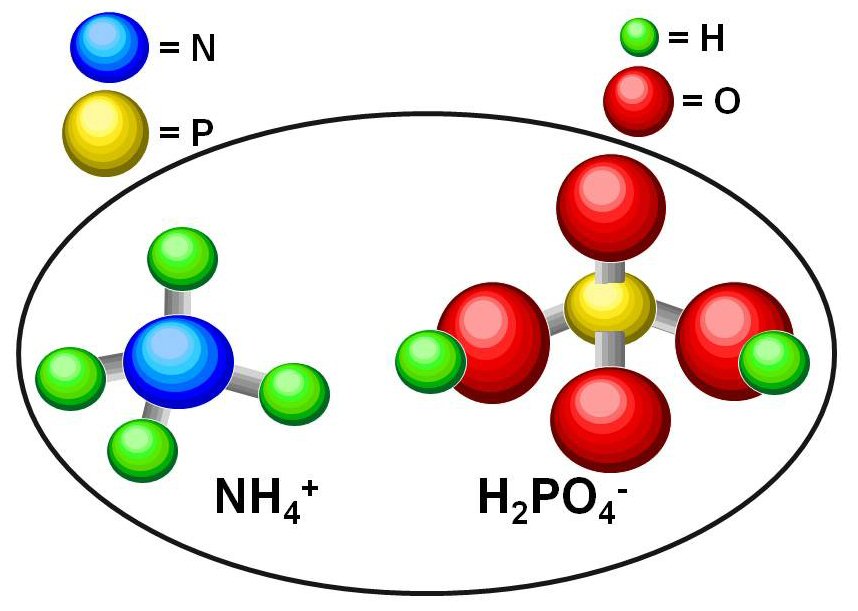

DAP fertilizer is an excellent source of P and nitrogen (N) for plant nutrition. It’s highly soluble and thus dissolves quickly in soil to release plant-available phosphate and ammonium. A notable property of DAP is the alkaline pH that develops around the dissolving granule.

Once in the soil, the ammonium ion in DAP is rapidly converted to nitrate by soil bacteria, resulting in a subsequent drop in pH. Therefore, the rise in soil pH surrounding DAP granules is a temporary effect. This initial rise in soil pH neighboring DAP can influence the micro-site reactions of phosphate and soil organic matter.

As dissolving DAP granules release ammonium, the seedlings and plant roots nearest the volatile ammonia can be harmed. This potential damage more commonly occurs when the soil pH is greater than 7, a condition that often exists around the dissolving DAP granule. To prevent such damage, users should avoid placing high concentrations of DAP near germinating seeds.

Differences in the initial chemical reaction between various commercial P fertilizers in soil become minor over time (within weeks or months) and are minimal as far as plant nutrition is concerned. Most field comparisons between DAP and monoammonium phosphate (MAP) show only minor or no differences in plant growth and yield due to P source with proper management.

DAP also acts as a fire retardant. For example, a mixture of DAP and other ingredients can be spread in advance of a fire to prevent a forest from burning. It then becomes a nutrient source after the danger of fire has passed. DAP is used in various industrial processes, too, such as metal finishing. And, it’s commonly added to wine to sustain yeast fermentation and to milk to produce cheese cultures.

It is the most popular phosphatic fertilizer because of its high analysis and good physical properties. The composition of DAP is N-18% and P2O5-46%.

| Moisture % by weight, maximum | 2.5 |

| Total N % by weight, minimum | 18 |

| Ammonical nitrogen % by weight, minimum | 15.5 |

| BIURET | 1.0% maximum |

| Available Phosphorus (as P2O5)% by weight, minimum | 46.0 |

| Water Soluble Phosphorus (as P2O5)% by weight, minimum | 39.5 |

| Particle size: Minimum 90% of the material be retained on 1 mm and 4 mm IS sieve |

Urea is a white crystalline substance with the chemical formula CO(NH2)2. It is highly soluble in water and contains 46.7% nitrogen. Urea, also known as carbamide, is an organic compound because it contains carbon. It was the first organic compound ever synthesized by chemists; this was accomplished by accident in 1828 by the German chemist Friedrich Wöhler.

Urea is made by reacting carbon dioxide (CO2) with anhydrous ammonia (NH3) at pressures above 14,000 kPa (2000 psi) and temperatures above 180 °C in a two-step process:

CO2 + 2NH3 → NH2COONH4 → CO(NH2)2 + H2OThe water produced during the reaction must be removed by dehydration to maximize the yield. The resulting molten mixture is then further processed into either prills (solidified pellets) or granules.

Urea also occurs naturally in urine (hence its name). We each excrete 20 to 30 grams of urea a day.

As urea contains 46.7% nitrogen, each tonne supplies 467 kg of nitrogen. For comparison, a tonne of ammonium nitrate supplies only 350 kg of nitrogen, and a tonne of ammonium sulfate supplies only 212 kg of nitrogen. The high nitrogen content means lower transport and application costs per tonne of nitrogen.

This depends on the environmental conditions. When soil conditions are favorable for microbial activity – in other words, warm and moist with an appropriate pH – the conversion is rapid and will begin within a few days. In a band application, it may continue for a month or more.

Urea contains about one-third more nitrogen, is less corrosive, and is less prone to caking. Also, until nitrification occurs, the nitrogen is less subject to leaching or denitrification than the nitrate portion of the ammonium nitrate.

| Product | UREA N46 agriculture grade |

|---|---|

| Nitrogen | 46% minimum |

| Moisture | 0.5 max |

| Free ammonia | 160 PXT PPM maximum |

| BIURET | 1.0% maximum |

| Harmful substances | 100 % free from harmful substances |

| Melting point | 132 degree Celsius |

| Granulation | 1mm to 4mm 90% minimum |

| Color | White standard or white pure |

| Odor | Odorless |

| Boiling | Decomposes before boiling |

| Radiation | Non-radioactive |

| Physical state | Solid@20°C, 101 KPA white granules |

| Specific gravity | Solid@20° C-1.35 t/ms |

| Floatability in water | Sinks and mixes |

| Molecular weight | 60.065 |

| Fertilizer granular | 94-96%min |

| Prill | 96% max |

| Fisher | 0.30% |

| Product | UREA N46 agriculture grade |

|---|---|

| Nitrogen | 46% minimum |

| Moisture | 0.5 max |

| Free ammonia | 160 PXT PPM maximum |

| BIURET | 1.0% maximum |

| Harmful substances | 100 % free from harmful substances |

| Melting point | 132 degree Celsius |

| Granulation | 1mm to 4mm 90% minimum |

| Color | White standard or white pure |

| Odor | Odorless |

| Boiling | Decomposes before boiling |

| Radiation | Non-radioactive |

| Physical state | Solid@20°C, 101 KPA white granules |

| Specific gravity | Solid@20° C-1.35 t/ms |

| Floatability in water | Sinks and mixes |

| Molecular weight | 60.065 |

| Fertilizer granular | 94-96%min |

| Prill | 96% max |

| Fisher | 0.30% |