Melamine powder is tasteless, odorless, and non-toxic. Melamine formaldehyde resins used for laminates offer good hardness, resistance to scratch, stain, water, and heat. Laminates used in some industrial electrical applications possess high mechanical strength, good heat resistance, and good electrical insulating properties.

Asbestos-filled melamine resins possess very high dielectric strength and high heat resistance. Besides the best dimensional stability, melamine formaldehyde molding powder gives clear and bright colors, is easily moldable, and offers resistance to surface scratching.

For table tops, kitchen shelves, platforms, wall cladding, bus bodies, interior of railway coaches, counters, deckings, instrument panels.

Bowls, trays, spatulas, mixer's base, crockery, cutlery items, launderable buttons, lamp shades.

Circuit breakers, television tube support, automotive ignition components, washing machine, agitators, soda fountain parts, switch gears, switch housings, connector plus inserts, wattmeter terminal block, junction boxes, fuse carriers, plating tanks.

For currencies, toilet paper, facial tissues, shopping and shipping bags, map papers, food wrappers, photographic paper.

For motorcars, refrigerator cabinets, washing machines, kitchen equipment, typewriters, water heaters.

Melamine adhesives from Melamine resins are extra strong, extra tough, highly water resistant, and colorless (veneered doors).

For providing anti-crease treatment to cotton and other fabrics.

MF resins act as pre-tanning agents.

| Test | Specification |

|---|---|

| Rapid Test | Clear to sight turbid |

| Shift during heating | 0.8% Max. |

| Colour Alpha (after filtration) | 20 Unit Max. |

| Moisture | 0.1% Max. |

| Cold Water Insoluble | W:43:0.05% Max. |

| Bulk Density | 800-1100 gm/Ltr. |

| Assay | 99.8% Min. |

In 25 Kg. multiwall craft paper bag.

| Name | Ferric Chloride Solution (40%+) |

| Synonyms: | Iron chloride, Iron III Chloride, Iron Tri Chloride |

| CAS #: | 7705-08-0 |

| Formula: | FeCl3 |

| Molecular Wt. | 162.2 (100% Basis) |

| Chemical Classification: | Inorganic Acidic Salt, Solution |

| ITC Number: | 28273300 |

| BIS No: | IS 711:1970 |

| CAS No. : | 7705-08-0 |

| EINECS No. : | 231-729-4 |

| Form | Liquid Solution with 40 % Ferric Chloride in water |

| Specific Gravity | 1.42 |

| Appearance: | Dark Brown Liquid |

| Boiling Point: | 106C (223 |

| PH: | <2 (less than 2) |

| Solubility in Water: | Complete |

| Vapour Pressure: | 40 mmHg @ 35° C |

| % Volatile | 55-73% (Water) |

| Evaporation Ratio: | None Found |

| Odor: | Slightly Acidic |

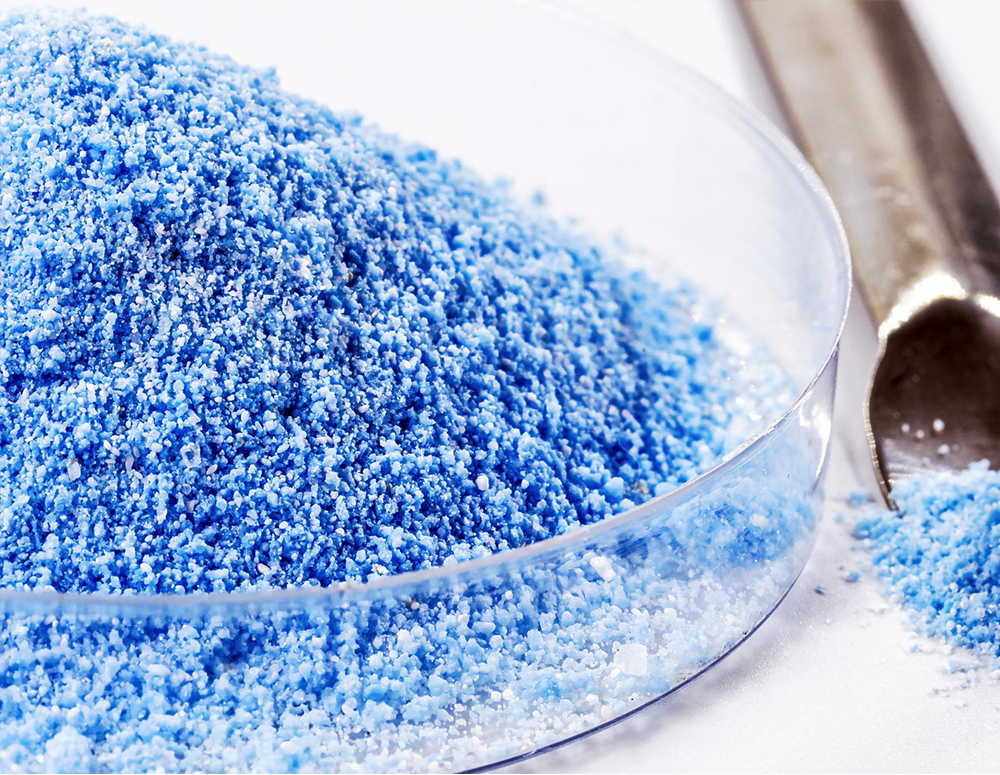

Algaecides are chemicals that kill algae and blue or green algae when they are added to water. Examples are copper sulfate, iron salts, rosin amine salts, and benzalkonium chloride. Algaecides are effective against algae but are not very usable for algal blooms for environmental reasons. The problem with most algaecides is that they kill all present algae, but they do not remove the toxins that are released by the algae prior to death.

Foam is a mass of bubbles created when certain types of gas are dispersed into a liquid. Strong films of liquid then surround the bubbles, forming large volumes of non-productive foam. The cause of foam is a complicated study in physical chemistry, but we already know that its existence presents serious problems in both the operation of industrial processes and the quality of finished products. When it is not held under control, foam can reduce the capacity of equipment and increase the duration and costs of processes.

Antifoam blends contain oils combined with small amounts of silica. They break down foam thanks to two of silicone's properties: incompatibility with aqueous systems and ease of spreading.

Antifoam compounds are available either as powder or as an emulsion of the pure product.

Antifoam powder covers a group of products based on modified polydimethylsiloxane. The products vary in their basic properties, but as a group they introduce excellent antifoaming in a wide range of applications and conditions.

The antifoams are chemically inert and do not react with the medium that is defoamed. They are odorless, tasteless, non-volatile, non-toxic and they do not corrode materials. The only disadvantage of the powdery product is that it cannot be used in watery solutions.

Antifoam powder covers a group of products based on modified polydimethylsiloxane. The products vary in their basic properties, but as a group they introduce excellent antifoaming in a wide range of applications and conditions.

The antifoams are chemically inert and do not react with the medium that is defoamed. They are odorless, tasteless, non-volatile, non-toxic and they do not corrode materials. The only disadvantage of the powdery product is that it cannot be used in watery solutions.

In laboratory tests, a maximum tolerable microbial population limit in systems is determined. When these data are known, in many cases, the number of bacteria and other microorganisms needs serious reduction. This can be accomplished by the addition of biocides; chemical compounds that are toxic to the present microorganisms. Biocides are usually slug-fed to a system to bring about rapid, effective population reductions from which the microorganisms cannot easily recover. There are various different biocides, some of which have a wide range of effects on many different kinds of bacteria. They can be divided up into oxidizing agents and non-oxidizing agents.

Chlorine is the most widely used industrial biocide today. It has been used for disinfection of domestic water supplies and for the removal of tastes and odors from water for a long time. The amount of chlorine that needs to be added in a water system is determined by several factors, namely chlorine demand, contact time, pH, and temperature of the water, the volume of water, and the amount of chlorine that is lost through aeration. When chlorine gas enters a water supply it will hydrolyze to form hypochlorous and hydrochlorous acid. The latter determines the biocidal activity. This process takes place according to the following reaction:

Cl2 + H2O -> HOCl + HCl

Hydrochlorous acid is responsible for the oxidation reactions with the cytoplasm of microorganisms, after diffusion through the cell walls. Chlorine then disturbs the production of ATP (adenosine triphosphate), an essential compound for the respiration of microorganisms. The bacteria that are present in the water will die as a consequence of experienced breathing problems, caused by the activity of the chlorine.

The amount of chlorine that needs to be added for the control of bacterial growth is determined by the pH. The higher the pH, the more chlorine is needed to kill the unwanted bacteria in a water system. When the pH values are within a range of 8 to 9, 0.4 ppm of chlorine must be added. When the pH values are within a range of 9 to 10, 0.8 ppm of chlorine must be added.

Chlorine dioxide is an active oxidizing biocide that is applied more and more due to the fact that it has less damaging effects on the environment and human health than chlorine. It does not form hydrochlorous acids in water; it exists as dissolved chlorine dioxide, a compound that is a more reactive biocide at higher pH ranges.

Chlorine dioxide is an explosive gas, and therefore it has to be produced or generated on-site, by means of the following reactions:

Cl2 + 2 NaClO2 -> 2 NaCl + 2 ClO2

2 HCl + 3 NaOCl + NaClO2 -> 2 ClO2 + 4 NaCl + H2O.

Chloroisocyanurates are applied more and more due to the fact that they have less damaging effects on the environment and human health than chlorine. They do not form hydrochlorous acids in water; they exist as dissolved chlorine dioxide, a compound that is a more reactive biocide at higher pH ranges.

Chlorine dioxide is an explosive gas, and therefore it has to be produced or generated on-site, by means of the following reactions:

Cl2 + 2 NaClO2 -> 2 NaCl + 2 ClO2

2 HCl + 3 NaOCl + NaClO2 -> 2 ClO2 + 4 NaCl + H2O.

Hypochlorite is a salt from hypochlorous acid. It is formulated in several different forms. Usually, hypochlorite is applied as sodium hypochlorite (NaOCl) and calcium hypochlorite (Ca(OCl)2). These compounds can be applied as biocides. They function in very much the same way as chlorine, although they are a bit less effective.

Ozone is naturally unstable. It can be used as a powerful oxidizing agent when it is generated in a reactor. As a biocide, it acts in much the same way as chlorine; it disturbs the formation of ATP, so that the cell respiration of microorganisms will be made difficult. During oxidation with ozone, bacteria usually die from the loss of life-sustaining cytoplasm.

While the oxidation process takes place, ozone splits into oxygen and an ozone atom, which is lost during the reaction with cell fluids of the bacteria:

O3 -> O2 + (O)

A number of factors determine the amount of ozone required during oxidation, these are pH, temperature, organics and solvents, and accumulated reaction products.

Ozone is more environmentally friendly than chlorine because it does not add chlorine to the water system. Due to its decomposition to oxygen, it will not harm aquatic life.

Usually, 0.5 ppm of ozone is added to a water system, either on a continuous or intermittent basis.

Acrolein is an extremely effective biocide that has an environmental advantage over oxidizing biocides because it can easily be deactivated by sodium sulfite before discharge to a receiving stream. Acrolein has the ability to attack and distort protein groups and enzyme synthesis reactions. It is usually fed to water systems as a gas in amounts of 0.1 to 0.2 ppm in neutral to slightly alkaline water. Acrolein is not used very frequently, as it is extremely flammable and also toxic.

Amines are effective surfactants that can act as biocides due to their ability to kill microorganisms. They can enhance the biocidal effect of chlorinated phenolics when they are applied in water.

Chlorinated phenolics, unlike oxidizing biocides, have no effect on the respiration of microorganisms. However, they do induce growth. The chlorinated phenolics first adsorb to the cell wall of microorganisms by interaction with hydrogen bonds. After adsorption to the cell wall, they will diffuse into the cell where they go into suspension and precipitate proteins. Due to this mechanism, the growth of the microorganisms is inhibited.

Copper salts have been used as biocides for a long time, but their use has been limited in recent years due to concerns about heavy metal contamination. They are applied in amounts of 1 to 2 ppm. When the water that is treated is located in steel tanks, copper salts should not be applied because of their ability to corrode steel. Copper salts should not be used in water that will be applied as drinking water either because they are toxic to humans.

Organo-sulfur compounds act as biocides by inhibiting cell growth. There are a variety of different organo-sulfur compounds that function in different pH ranges. Normally, energy is transferred in bacterial cells when iron reacts from Fe3+ to Fe2+. Organo-sulfur compounds remove the Fe3+ by complexing as an iron salt. The transfer of energy through the cells is then stopped and immediate cell death will follow.

Quaternary ammonium salts are surface-active chemicals that generally consist of one nitrogen atom, surrounded by substitutes containing eight to twenty-five carbon atoms on four sides of the nitrogen atom. These compounds are generally most effective against bacteria in alkaline pH ranges. They are positively charged and will bond to the negatively charged sites on the bacterial cell wall. These electrostatic bonds will cause the bacteria to die from stresses in the cell wall. They also cause the normal flow of life-sustaining compounds through the cell wall to stop, by declining its permeability.

Use of quaternary ammonium salts is limited due to their interaction with oil when this is present and the fact that they can cause foaming.

Oxygen scavenging means preventing oxygen from introducing oxidation reactions. Most of the naturally occurring organics have a slightly negative charge. Due to that, they can absorb oxygen molecules, because these carry a slightly positive charge, to prevent oxidation reactions from taking place in water and other liquids.

Oxygen scavengers include both volatile products, such as hydrazine (N2H4) or other organic products like carbohydrazine, hydroquinone, diethylhydroxyethanol, methylethylketoxime, but also non-volatile salts, such as sodium sulfite (Na2SO3) and other inorganic compounds, or derivatives thereof. The salts often contain catalyzing compounds to increase the rate of reaction with dissolved oxygen, for instance, cobalt chloride.

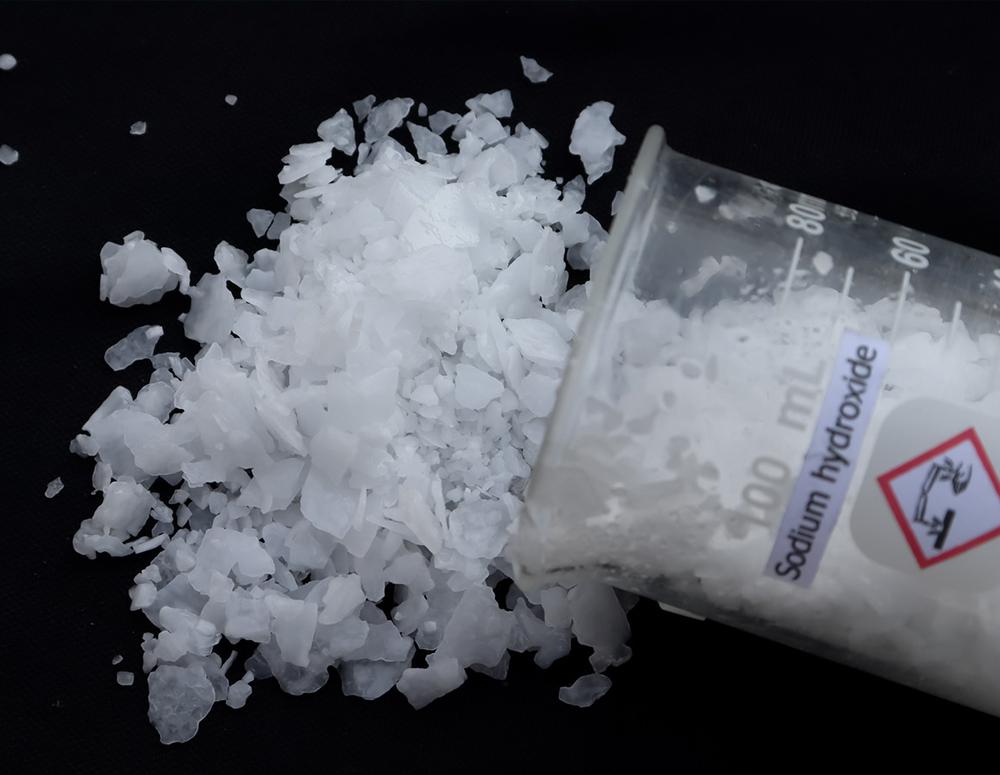

Municipal water is often pH-adjusted to prevent corrosion from pipes and to prevent the dissolution of lead into water supplies. During water treatment, pH adjustments may also be required. The pH is brought up or down through the addition of basics or acids. An example of lowering the pH is the addition of hydrogen chloride, in case of a basic liquid. An example of bringing up the pH is the addition of sodium hydroxide, in case of an acidic liquid.

The pH will be converted to approximately seven to seven and a half, after the addition of certain concentrations of acids or bases. The concentration of the substance and the kind of substance that is added depend on the necessary decrease or increase of the pH.

Ion exchange resins need to be regenerated after application, after that, they can be reused. But every time the ion exchangers are used, serious fouling takes place. The contaminants that enter the resins will not be removed through regeneration; therefore, resins need cleaning with certain chemicals.

Chemicals that are used are, for instance, sodium chloride, potassium chloride, citric acid, and chlorine dioxide.

Chlorine dioxide cleansing serves the removal of organic contaminants on ion exchange resins. Prior to every cleaning treatment, resins should be regenerated. After that, in the case chlorine dioxide is used, 500 ppm of chlorine dioxide in a solution is passed through the resin bed and oxidizes the contaminants.

Scale is the precipitate that forms on surfaces in contact with water as a result of the precipitation of normally soluble solids that become insoluble as temperature increases. Some examples of scale are calcium carbonate, calcium sulfate, and calcium silicate.

Scale inhibitors are surface-active negatively charged polymers. As minerals exceed their solubilities and begin to merge, the polymers become attached. The structure for crystallization is disrupted, and the formation of scale is prevented. The particles of scale combined with the inhibitor will then be dispersed and remain in suspension.

Examples of scale inhibitors are phosphate esters, phosphoric acid, and solutions of low molecular weight polyacrylic acid.

Due to the properties of caustic soda, it is used in many different industries. Here is a brief list of these industries:

In the pharmaceutical industry

In the cosmetic industry

In the alcohol industry

In the battery industry and neutralizing the acid

In the ceramic tile industry

In the industries of detergents and soaps

In the paper and carton industry

In the oil and gas industry

In the textile and leather industries

In Rose Painting Industries

In oil and gas and petrochemical industries

In the chemical industry

In the silk industry

In laboratories to determine the concentration of acids in experiments

In the glue manufacturing industry

In industries as the disinfectant

Recovery of rubber

Caustic soda, known as Sodium Hydroxide, is a chemical substance used in various industries. It is an odorless, white crystalline, transparent, non-volatile, and highly corrosive compound that easily absorbs air humidity. When dissolved in water or neutralized with acid, it produces a considerable amount of heat.

Caustic soda has a variety of features, which make this highly consumable material in many

industries very popular.

Among these features are the following:

Strong fat and oil remover

Neutralize acidic environments

PH adjuster

| Brand | Caustic Soda |

| Scientific name | Sodium Hydroxide |

| Chemical formula | Na-OH |

| Melting point | 1390 ° C |

| Density | 2.13 |

| The molecular weight of caustic soda | 01/40 |

| The melting point of interest | 12 ° C |

| Spot boiling point | 140 ° C |

| Relative density of percolation | 53.1% (50% solution), 2 at 5.5 ° C (solution 73% -70%) |

| Peroxide solubility in water | 109 g / 100 ml at 20 ° C |